Code of Responsible Business Conduct

(based on OECD Due Diligence Guidance for Responsible Supply Chains in the Garment and Footwear Sector, OECD Publishing, Paris)

Respect is a requisite of freedom, and as such, it is a core value of Hosn. Through working together, we can support society while nurturing our environment, enabling humanity to progress beyond its current state. Hosn hope to contribute a bit of confidence to reduce unnecessary struggles, allowing people to focus on the bigger picture, beyond short-term profits and unbalanced human interactions.

From a practical point of view, Hosn can reduce the number of garments needed, contribute to a shift away from seasonal fashion, and support sustainable resources for production.

Our contribution is our reputation. And that reflects the value of our brand. By raising social and environmental awareness with our customers, we can both expand our competitive advantage, attract suitable business and retail partners, and offer a positive contribution to the long-term development of our world.

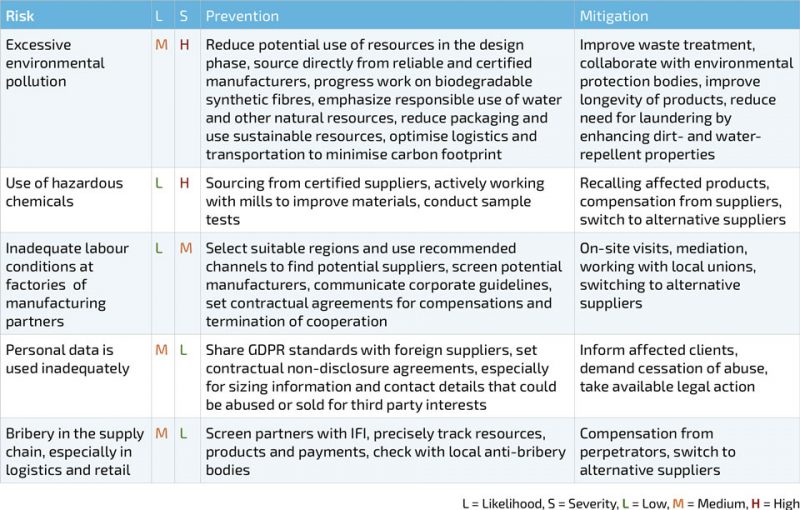

As a business of the 21st century, we take our global responsibility seriously. Risks need to be avoided by identifying them as early as possible, coming up with solutions to avoid adverse impacts and address them as efficiently as possible, should they occur.